“Facts Speak Louder Than Words”. In this article you will see: 18 international Authoritative Tests & Certifications Prove KKR Solid Surface’s Excellence, demonstrating scientifically verified superior performance that delivers safe, durable, and cost-effective solutions for your projects.

👉 Want the full 64-page SGS test reports? Contact us now to get the complete certification PDF.

Overview: 18 Key Tests & Certifications of KKR® Solid Surface

KKR’s solid surface material has undergone rigorous testing by SGS and other accredited labs, ensuring it meets global standards for safety, durability, and performance.

Below is a high-level summary of its verified properties:

| Category | Key Certifications/Test Results | Competitive Advantage |

|---|---|---|

| Safety | – No crystalline silica (safe for cutting/sanding) – Lead/Cadmium-free (Prop 65 compliant) – CE Mark (EU compliance) – CUPC Certification (North America plumbing standards) | Meets strict EU/U.S./AUS/Canada regulations; ideal for health-conscious markets. |

| Durability | – Mohs 3 / Barcol 62 hardness (scratch-resistant) – 56.4 MPa flexural strength (stronger than marble) – Impact resistance: 10.56 J (withstands drops) – Thermal shock resistance (no cracks after 1,000 hot/cold cycles) | Long lifespan, fewer warranty claims, and ideal for high-traffic areas. |

| Heat & Fire Resistance | – Class B-s1, d0 fire rating (low flammability, minimal smoke) – No damage at 180°C (ANSI/NEMA LD 3-2005) | Safe for kitchens, fire-prone areas, and outdoor use. |

| Hygiene & Cleanability | – Mold-resistant (ISO 16869: zero growth) – Stain-resistant (C4 grade) – Non-porous (easy to sanitize, EN 14516) | Perfect for hospitals, restaurants, and homes with kids. |

| Aesthetic Stability | – UV-resistant (ΔE*ab 2.0 after 300h xenon exposure) – Dimensional stability (≤0.01mm warping) | No fading or warping—maintains looks for decades. |

| Installation Flexibility | – Slip-resistant (EN 14231: dry SRV >63) – Thermal conductivity 0.447 W/(m·K) (mild insulation) | Safe for wet areas, versatile for indoor/outdoor use. |

What‘s KKR Test & Certificate? How Can They Benefit My Project?

Choose with Data, Win with Quality—KKR’s 18 certifications are your most reliable “technical credentials” in the supply chain.

1. Crystalline Silica Content Test

What Is The Crystalline Silica Content Test?

Crystalline silica content test checks whether the solid surface material contains crystalline silica, a harmful substance that can cause health issues (like lung disease) if inhaled as dust during cutting or installation.

Why Crystalline Silica Content Test Is Important For Importers?

- Safety Compliance: Many countries (e.g., the U.S., Aus, EU) strictly regulate silica content in building materials. A “Pass” means the product meets safety standards, avoiding legal risks.

- Worker/User Protection: Ensures no health hazards during fabrication or daily use.

- Market Trust: Buyers prefer certified products, giving you a competitive edge.

KKR’s Crystalline Silica Content Test Result

- Method: Tested by SGS using FTIR, EDX, and XRD (advanced lab techniques).

- Result: No crystalline silica detected – completely safe.

Benefits When Importing from KKR

- No customs rejections due to hazardous material violations.

- Easier sales with safety certifications for health-conscious markets.

- Reduced liability for installers and end-users.

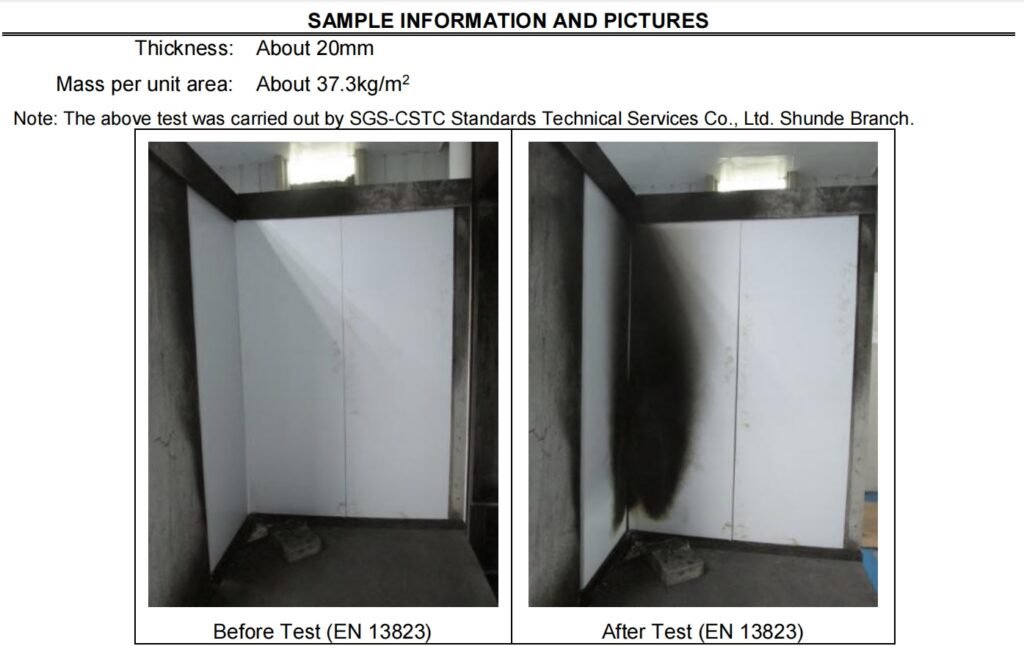

2. Fire Resistance Test (EN 13501-1:2007)

What Is The Fire Resistance Test?

Fire resistance test evaluates how the solid surface material reacts to fire, including flame spread, smoke production, and burning droplets. It classifies materials into safety levels (e.g., Class A1 = non-combustible, Class B = low flammability).

Why Fire Resistance Test Is Important For Importers?

- Building Code Compliance: Many countries require fire-rated materials for kitchens, bathrooms, and commercial spaces.

- Safety Assurance: Reduces fire hazards in homes, hotels, and offices.

- Higher Market Value: Fire-safe materials are preferred in contracts (e.g., government projects, high-end real estate).

KKR’s Fire Resistance Test Result

- Standard: EN 13501-1:2007 (EU fire safety standard).

- Rating: Class B-s1, d0 – meaning:

- B: Low flammability (does not easily catch fire).

- s1: Minimal smoke production (safer evacuation in fires).

- d0: No flaming droplets (prevents fire from spreading downward).

Benefits When Importing from KKR

- Meets EU/US fire regulations – no delays in approvals.

- Ideal for kitchens, hospitals, and public spaces where fire safety is critical.

- Competitive advantage over non-certified suppliers.

3. Hardness Tests (Mohs & Barcol Index)

What Is Hardness Tests?

Hardness tests measure the scratch resistance (Mohs scale) and surface hardness (Barcol scale) of the solid surface material.

- Mohs Hardness: Rates minerals from 1 (softest, like talc) to 10 (hardest, like diamond).

- Barcol Hardness: Measures surface indentation resistance (higher = harder).

Why Hardness Tests Is Important For Importers?

- Durability: Determines how well the material resists scratches, dents, and wear in daily use.

- Suitability for Applications:

- Kitchen countertops need high scratch resistance.

- Bathroom vanities should resist cosmetic damage.

- Customer Satisfaction: Harder surfaces last longer, reducing complaints.

KKR’s Hardness Test Results

- Mohs Hardness: 3 (similar to calcite, harder than gypsum but softer than quartz).

- What this means: Resists minor scratches but may show wear from sharp objects (e.g., knives).

- Barcol Hardness: 62 (on a 0–100 scale, where 60+ is considered durable for solid surfaces).

- What this means: Good resistance to dents and surface impacts.

Benefits When Importing from KKR

- Longer-lasting products → Fewer warranty claims.

- Easier to market as a “scratch-resistant” premium material.

- Better for high-traffic areas (hotels, offices, kitchens).

4. Stain Resistance Test (EN 14617-10:2012)

What Is Stain Resistance Test?

Stain resistance test checks how well the solid surface material resists stains from common household substances like wine, vinegar, oil, and dyes. The material is exposed to these liquids for set periods (1 hour and 24 hours) and then inspected for permanent marks.

Why Stain Resistance Test Is Important For Importers?

- Easy Maintenance: Stain-resistant surfaces stay looking new with simple cleaning.

- Customer Appeal: Homeowners and businesses prefer surfaces that won’t discolor over time.

- Long-Term Value: Reduces replacement costs and keeps interiors looking premium.

KKR’s Stain Resistance Test Results

- Passed against red wine, vinegar, and lipstick (no stains after 24 hours).

- Chemical Resistance Classification: C4 (highest grade for agglomerated stone, meaning it retains over 80% of its original appearance after harsh chemical exposure).

Benefits When Importing from KKR

- Low-maintenance product → Happy customers, fewer complaints.

- Ideal for kitchens & bathrooms where spills are common.

- Competitive edge over cheaper, non-stain-resistant alternatives.

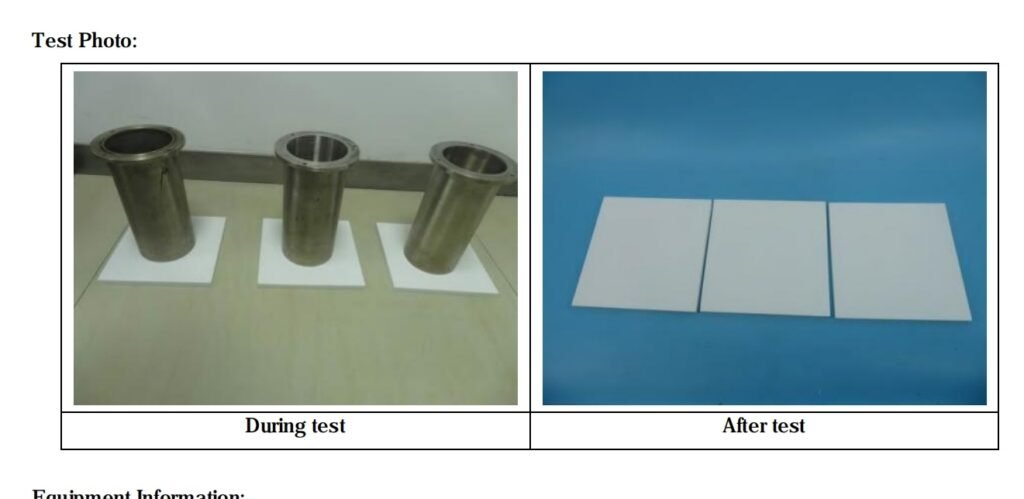

5. Thermal Shock Resistance Test (EN 14617-6:2012)

What Is Thermal Shock Resistance Test?

Thermal shock resistance test evaluates how well the solid surface material withstands sudden temperature changes, such as placing a hot pan on a cold countertop or pouring boiling water into a sink. The material undergoes repeated cycles of extreme heat and cold to check for cracks, warping, or strength loss.

Why Thermal Shock Resistance Test Is Important For Importers?

- Real-World Durability: Kitchens and bathrooms face rapid temperature swings (hot pans, cold drinks, steam, etc.). A material that cracks under thermal stress leads to unhappy customers.

- Safety: Prevents structural failures that could cause injuries or property damage.

- Longevity: Resists damage from daily use, reducing warranty claims.

KKR’s Thermal Shock Resistance Test Results

- 20 cycles of extreme heat/cold exposure (simulating years of use).

- Mass loss: Only 0.11% (negligible wear).

- Flexural strength after testing: 54.8 MPa (vs. original 56.4 MPa – just 2.8% strength loss).

- Visual inspection: No cracks, discoloration, or surface damage.

Benefits When Importing from KKR

- Reliable for kitchens & bathrooms – no cracking from hot/cold exposure.

- Lower return rates – customers won’t complain about warping or damage.

- Premium positioning – market it as “heat-resistant” for kitchens.

6. Impact Resistance Test (EN 14617-9:2005)

What Is Impact Resistance Test?

Impact resistance test measures how well the solid surface material withstands sudden impacts—like dropping a heavy pot or tool—without cracking or breaking. A steel ball is dropped from increasing heights until the material fractures, and the energy absorbed (in joules) is recorded.

Why Impact Resistance Test Is Important For Importers?

- Real-World Durability: Kitchens, bathrooms, and commercial spaces face accidental impacts. A fragile material means more breakage and customer complaints.

- Safety: Chips or cracks can create sharp edges, posing injury risks.

- Cost Savings: Durable materials reduce replacements and warranty claims.

KKR’s Impact Resistance Test Results

- Average fracture energy: 10.56 J (higher than many competing solid surfaces).

- Comparison:

- Typical laminate countertops: ~5–8 J.

- Natural stone (e.g., marble): ~3–7 J (more brittle).

- Visual result: No splintering or sharp edges upon impact.

Benefits When Importing from KKR

- Fewer breakages during shipping/installation – saves money on replacements.

- Longer lifespan – resists daily wear and tear in busy households or businesses.

- Marketing advantage – highlight “high-impact resistance” for commercial buyers (restaurants, hotels).

7. Slip Resistance Test (EN 14231:2003)

What Is Slip Resistance Test?

Slip resistance test evaluates how slip-resistant the solid surface material is under both dry and wet conditions, using a pendulum friction tester. The results are given as SRV (Slip Resistance Value)—higher numbers mean better grip.

Why Slip Resistance Test Is Important For Importers?

- Safety Compliance: Many countries require slip-resistant surfaces for commercial kitchens, bathrooms, and public spaces.

- Liability Reduction: Prevents costly lawsuits from slip-and-fall accidents.

- Customer Preference: Homes with kids/elders prioritize slip-resistant flooring.

KKR’s Slip Resistance Test Results

- Dry Surface SRV: >63 (excellent grip, safe for most applications).

- Wet Surface SRV: <30 (meets basic safety standards but may need textured finishes for pools/spas).

- Comparison:

- Ceramic tile (wet): ~10–20 (more slippery).

- Textured granite (wet): ~25–35 (similar to KKR).

Your Benefit When Importing from KKR

- Passes safety regulations for commercial installations (restaurants, hotels).

- Fewer accidents = happier customers and lower liability risks.

- Customizable – can add anti-slip textures for wet areas.

8. Chemical Resistance Test (EN 14617-10:2012)

What Is Chemical Resistance Test?

Chemical resistance test evaluates how well the solid surface material resists damage from common household and industrial chemicals, including:

- Acids (e.g., vinegar, cleaning agents)

- Alkalis (e.g., bleach, detergents)

- Staining agents (e.g., coffee, dyes)

The material is exposed to these substances for extended periods (1–8 hours), then inspected for discoloration, etching, or surface degradation.

Why Chemical Resistance Test Is Important For Importers?

- Real-World Performance: Kitchens, labs, and hospitals need surfaces that won’t degrade from spills or cleaning chemicals.

- Low Maintenance: Resistant materials save customers time and money on repairs/refinishing.

- Aesthetic Longevity: Prevents ugly stains or dull spots over time.

KKR’s Chemical Resistance Test Results

- Classification: C4 (highest grade for agglomerated stone).

- Retains >80% of original appearance after 8 hours of exposure to harsh chemicals.

- No permanent damage from common agents like vinegar, bleach, or alcohol.

- Stain Test Highlights:

- Red wine, coffee, oil: No penetration after 24 hours.

- Hair dye: Minor staining (can be cleaned with mild abrasives).

Benefits When Importing from KKR

- Zero worry about chemical damage – ideal for labs, hospitals, and commercial kitchens.

- Easy to clean – customers won’t need special sealants or expensive cleaners.

- Premium branding – market as “chemically inert” for high-end projects.

9. Light & UV Resistance (ISO 105-B02:2014 / Xenon Arc Exposure)

What Is Light & UV Resistance Test?

Light & UV resistance test evaluates how well the solid surface material resists fading or discoloration when exposed to:

- Sunlight (UV rays)

- Artificial light (e.g., indoor lighting)

- Weathering (for outdoor applications)

Samples are subjected to intense UV light in a xenon arc chamber (simulating years of sun exposure in weeks) and checked for color changes.

Why Light & UV Resistance Test Is Important For Importers?

- Outdoor Use: Balconies, facades, and patio furniture need UV-stable materials.

- Interior Design: Ensures colors stay true in sunlit rooms, hotels, or retail spaces.

- Customer Satisfaction: No ugly fading = fewer complaints and replacements.

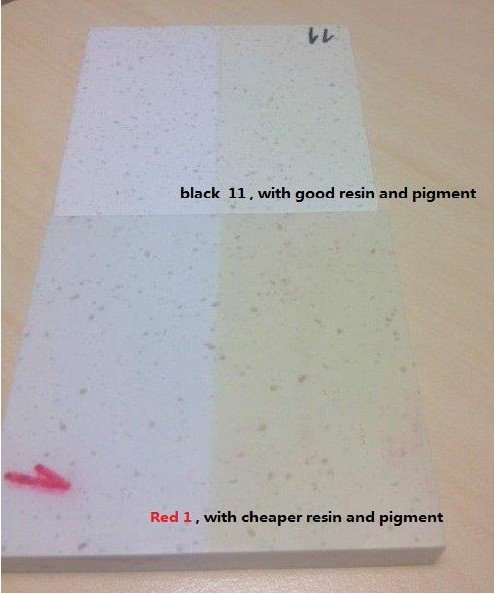

KKR’s Light & UV Resistance Test Results

- Xenon Arc Exposure (300 hours): ΔE*ab = 2.0 (minimal color shift, nearly undetectable to the human eye).

- ISO 105-B02 (Color Fastness): Grade 6+ (highest rating, better than blue wool reference).

- Comparison:

- Cheap laminates: ΔE*ab >5 (visible fading).

- Natural stone: Varies (some marbles/yellows fade faster).

- Comparison:

Benefits When Importing from KKR

- Guaranteed color stability – safe for outdoor installations or sunlit interiors.

- No “patchy” fading over time – maintains uniform appearance.

- Premium positioning – market as “fade-proof” for luxury projects.

10. Fungal Resistance Test (ISO 16869:2008)

What Is Fungal Resistance Test?

Fungal resistance test evaluates the material’s ability to resist mold and fungal growth, which is critical for humid environments like bathrooms, kitchens, and outdoor installations. Samples are exposed to high-humidity conditions and inoculated with common mold spores (e.g., Aspergillus niger, Penicillium) for 21 days, then inspected for growth.

Why Fungal Resistance Test Is Important For Importers?

- Health & Hygiene: Mold can cause allergies and respiratory issues—customers demand safe, easy-to-clean surfaces.

- Long-Term Durability: Fungal growth can degrade materials over time, leading to stains or structural damage.

- Commercial Demand: Hotels, hospitals, and schools prioritize mold-resistant surfaces.

KKR’s Fungal Resistance Test Results

- Fungal Growth Rating: 0 (no growth detected—highest possible resistance).

- Spore Concentration After 21 Days: 1.0 × 10⁶ spores/mL (no increase from baseline).

- Comparison:

- Porous materials (e.g., grout, cheap composites): Rapid mold growth.

- Non-porous surfaces (e.g., quartz, KKR): Inhibit mold.

Benefits When Importing from KKR

- Zero mold risk – ideal for wet areas (showers, pools, spas).

- Easy maintenance – no need for harsh chemical cleaners.

- Premium branding – market as “hygienic” or “hospital-grade.”

11. Lead & Cadmium Safety (Prop 65 / CPSC-CH-E1002-08.3)

What Is Lead & Cadmium Safety Test?

Lead & Cadmium Safety test checks for toxic heavy metals (lead and cadmium) in the solid surface material, complying with:

- California Proposition 65 (strict U.S. safety standard)

- Consumer Product Safety Commission (CPSC) guidelines

These metals are harmful if ingested or inhaled (e.g., during cutting/sanding) and are restricted in consumer products.

Why Lead & Cadmium Safety Test Is Important For Importers?

- Legal Compliance: Prop 65 violations can lead to fines or import bans in California (a major U.S. market).

- Consumer Trust: Families and businesses avoid products with toxic materials.

- Worker Safety: Ensures safe fabrication/installation (no dust hazards).

KKR’s Lead & Cadmium Safety Test Results

- Lead (Pb): Not Detected (<20 mg/kg, far below Prop 65’s 100 mg/kg limit).

- Cadmium (Cd): Not Detected (<5 mg/kg, well under the 300 mg/kg limit).

- Certification: PASSED all U.S. and EU safety thresholds.

Benefits When Importing from KKR

- Smooth customs clearance – no delays due to toxic material flags.

- Safe for kids/food contact – ideal for kitchens, schools, hospitals.

- Marketing edge – label as “heavy-metal-free” for eco-conscious buyers.

12. Thermal Conductivity & Resistance (EN 12664:2001)

What Is Thermal Conductivity & Resistance Test?

Thermal conductivity & resistance test measures how well the solid surface material conducts heat (important for applications like kitchen countertops, fireplace surrounds, or outdoor cladding). It also evaluates thermal resistance—the material’s ability to insulate against temperature transfer.

Why Thermal Conductivity & Resistance Test Is Important For Importers?

- Heat Safety: Customers want countertops that won’t scorch or crack from hot pans.

- Energy Efficiency: Low thermal conductivity = better insulation (good for exterior use).

- Comfort: Surfaces that stay cool/warm to the touch improve user experience.

KKR’s Thermal Conductivity & Resistance Test Results

- Thermal Conductivity: 0.447 W/(m·K)

- Comparison:

- Stainless steel: ~16 W/(m·K) (conducts heat rapidly).

- Granite: ~2.5–3.5 W/(m·K).

- Wood: ~0.15 W/(m·K) (insulates better).

- Comparison:

- Thermal Resistance: 0.044 (m²·K)/W

- Implication: Slower heat transfer than stone/metal, reducing risk of burns.

Benefits When Importing from KKR

- Safe for kitchens – won’t scorch easily (unlike stainless steel) or crack (unlike laminate).

- Versatile for indoor/outdoor use – resists temperature swings.

- Energy-efficient – adds mild insulation for buildings.

13. Flexural Strength Test (EN 14617-2:2016)

What Is Flexural Strength Test?

Flexural strength test measures the material’s bending strength—how much load it can bear before cracking or breaking. It’s critical for applications like long countertops, shelves, or cantilevered installations where the material must support weight without sagging or snapping.

Why Flexural Strength Test Is Important For Importers?

- Structural Safety: Ensures countertops won’t collapse under heavy objects (e.g., appliances, stone slabs).

- Design Flexibility: Allows for thinner profiles or longer unsupported spans.

- Durability: Resists cracking during transport/installation.

KKR’s Flexural Strength Test Results

- Average Flexural Strength: 56.4 MPa (megapascals).

- Comparison:

- Natural marble: ~15–20 MPa (weaker).

- Engineered quartz: ~50–60 MPa (similar).

- Laminate: ~30–40 MPa (much weaker).

- Comparison:

- Lower Expected Value: 49.4 MPa (worst-case scenario still outperforms many competitors).

Benefits When Importing from KKR

- Fewer breakages during shipping/installation – saves costs on replacements.

- Thinner, lighter designs possible – reduces material costs and eases handling.

- Ideal for large-format installations (e.g., conference tables, waterfall islands).

14. Dimensional Stability Test (EN 15388:2008)

What Is Dimensional Stability Test?

Dimensional stability test evaluates how much the solid surface material expands, contracts, or warps due to changes in temperature and humidity. It ensures the material maintains its shape and size over time, critical for seamless installations (e.g., large countertops, joint-free sinks).

Why Dimensional Stability Test Is Important For Importers?

- Seamless Joints: Prevents gaps or cracks in multi-piece installations (e.g., long countertops).

- Humidity Resistance: No warping in bathrooms, laundries, or outdoor kitchens.

- Precision Fit: Guarantees consistent sizing for easy replacement/installation.

KKR’s Dimensional Stability Test Results

- Dimensional Change: ≤ 0.01 mm (negligible expansion/contraction).

- Comparison:

- Natural wood: Can warp up to 5 mm in humid conditions.

- Cheap composites: Often show 0.1–0.5 mm movement.

- Flatness Tolerance: Meets EN 14617-16:2005 for modular tiles (no unevenness).

Benefits When Importing from KKR

- Flawless large-scale installations – no visible seams or buckling.

- No callbacks for warping or gaps (common with inferior materials).

- Easier CNC machining – precise cuts for complex designs.

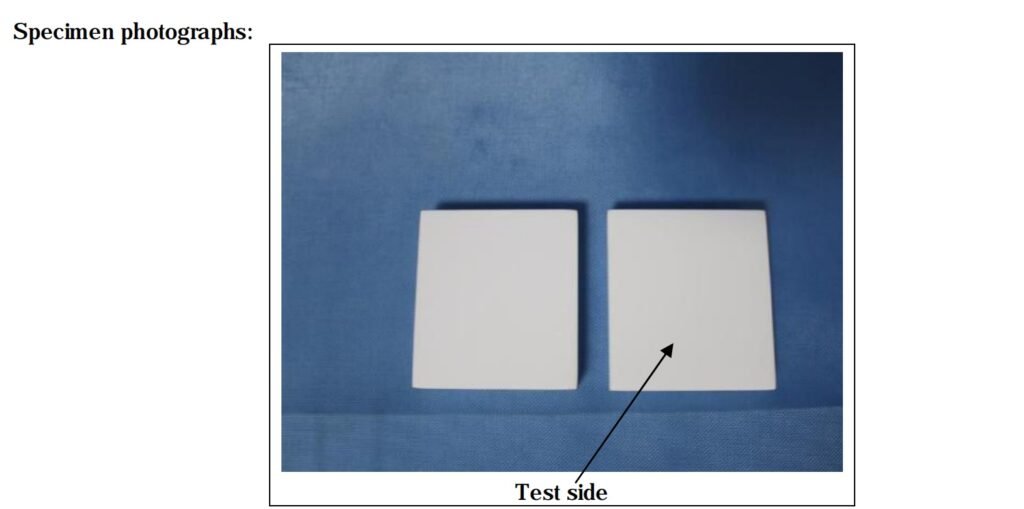

15. Cleanability & Hygiene Test (EN 14516:2006+A1:2010)

What Is Cleanability & Hygiene Test?

Cleanability & hygiene test evaluates how easy it is to clean the solid surface material and how well it resists bacterial growth. It simulates real-world scenarios like food spills, soap scum, and microbial contamination, measuring:

- Stain removal (with common cleaners)

- Surface smoothness (no pores for bacteria to hide)

- Chemical resistance (no damage from disinfectants)

Why Cleanability & Hygiene Test Is Important For Importers?

- Healthcare & Food Safety: Hospitals, restaurants, and kitchens need non-porous, sanitizable surfaces.

- Low Maintenance: Customers prefer materials that wipe clean effortlessly.

- Hygienic Marketing: “Bacteria-resistant” surfaces sell at premium prices.

KKR’s Cleanability & Hygiene Test Results

- Cleanability: PASS – stains (oil, coffee, ink) removed with water/mild detergent.

- Surface Porosity: Zero pores (prevents bacterial penetration, unlike natural stone).

- Chemical Resistance: No damage from bleach, alcohol, or ammonia-based cleaners.

Benefits When Importing from KKR

- Ideal for sterile environments (hospitals, labs, commercial kitchens).

- Reduced cleaning costs – no need for special sealants or polishes.

- Premium branding – market as “hospital-grade hygienic surface.”

16. CE Certification (EN 14688:2015+A1:2018)

What Is CE Certification?

The CE Mark confirms that KKR’s solid surface products comply with EU health, safety, and environmental standards for sanitary appliances (e.g., wash basins, kitchen sinks). It involves rigorous testing for:

- Mechanical strength

- Thermal shock resistance

- Chemical stability

- Hygiene and cleanability

Why CE Certificates Are Important For Importers?

- EU Market Access: Required to sell bathroom/kitchen products in Europe.

- Quality Assurance: CE certification is trusted by architects and contractors.

- Competitive Edge: Buyers prioritize certified products over uncertified alternatives.

KKR’s CE Certificates

- Standard: EN 14688:2015+A1:2018 (Sanitary Appliances – Wash Basins).

- Test Report: XMIN170300441CCM (conducted by SGS).

- Validity: Indefinite (as long as production remains consistent).

Benefits When Importing from KKR

- Effortless EU compliance – no need for retesting or documentation hassles.

- Faster project approvals – architects and specifiers demand CE-marked materials.

- Global credibility – even non-EU buyers associate CE with quality.

17. High-Temperature Resistance (ANSI/NEMA LD 3-2005)

What Is High-Temperature Resistance Test?

High-Temperature resistance test evaluates how well the solid surface material withstands direct heat exposure (e.g., hot pans, cooking tools, or hair styling appliances). Samples are exposed to 180°C (356°F) for 20 minutes and inspected for:

- Cracks, bubbles, or warping

- Color changes

- Surface texture degradation

Why High-Temperature Resistance Is Important For Importers?

- Kitchen & Bathroom Safety: Counters/sinks must tolerate hot items without damage.

- Aesthetic Durability: Prevents ugly scorch marks or discoloration.

- Commercial Use: Restaurants, salons, and labs need heat-resistant surfaces.

KKR’s High-Temperature Resistance Test Results

- Rating: “No Effect” (highest grade, no visible changes after testing).

- Comparison:

- Laminate: Melts/scorches at 150°C+.

- Natural stone: May crack under sudden heat (thermal shock).

Benefits When Importing from KKR

- No trivets needed – customers can place hot pots directly on the surface.

- Longer lifespan – resists damage from daily heat exposure.

- Premium kitchens/labs – market as “heat-proof” for high-end projects.

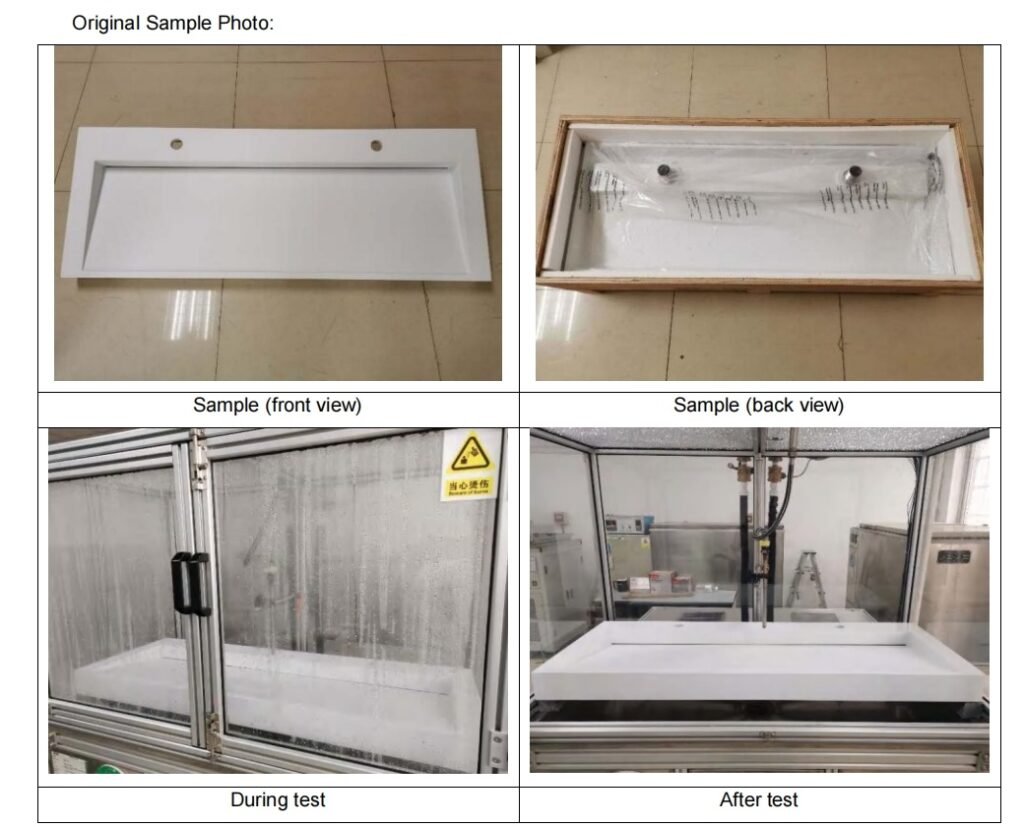

18. CUPC Certification (CSA B45.5-17/IAPMO 2174-2017)

What is the CUPC certification?

The CUPC (Canadian Uniform Plumbing Code) certification verifies that KKR’s solid surface basins and sinks meet North American plumbing standards for:

- Structural integrity (no cracking under load)

- Drainage efficiency

- Hygiene and cleanability

- Hot/cold water resistance

This certification is recognized in Canada and the U.S. (via IAPMO compliance).

Why CUPC Certificate Is Important For Importers?

- North American Market Access: Required to sell plumbing fixtures in Canada and accepted by many U.S. jurisdictions.

- Quality Assurance: Contractors and developers prioritize CUPC-certified products.

- Competitive Advantage: Certification proves compliance with strict North American safety standards.

KKR’s CUPC Certification

- Standard: CSA B45.5-17 / IAPMO 2174-2017 (for solid surface sanitaryware).

- Tests Passed:

- Drainage flow rate (≥0.2 L/sec for overflow).

- Thermal shock resistance (1,000 hot/cold cycles without damage).

- Load stability (150kg weight test).

Benefits When Importing from KKR

- Easy entry into U.S./Canadian markets – no need for retesting.

- Trusted by plumbers and architects – certification ensures hassle-free installations.

- Higher resale value – certified products justify premium pricing.

Start Your Luxury Project with Confidence at Kingkonree

With over 18 professional certificates and test reports, KKR stands for quality, trust, and innovation. From premium solid surface materials to full bathroom solutions, we’re here to bring your design vision to life—beautifully and reliably.

Contact our team today and let’s start building your next luxury project together.